Futuristic Building Materials To Watch For In 2017

As buildings around the world become higher and smarter, and are built faster, revolutionary building materials and features are being developed to make structures last longer and cost less.

We've listed five new concepts being brought into the development conversation which are set to change the game for the future of construction in all market sectors.

1. Paint That Can Sense Structural Cracks (below)

A team from North Carolina State University and the University of Eastern Finland are developing paint that can alert individuals when a structure is compromised.

The team has developed new “sensing skin” technology designed to serve as an early warning system for concrete structures, allowing authorities to respond quickly to damage in everything from nuclear facilities to bridges.

Dr. Mohammad Pour-Ghaz, an assistant professor of civil, construction and environmental engineering at NC State and co-author of a paper describing the work, said the paint can have life saving safety benefits.

“The idea is to identify problems quickly so that they can be addressed before they become big problems and – in the case of some critical infrastructure – so that public safety measures can be implemented,” Pour-Ghaz says.

How Does it Work?

The skin is an electrically conductive coat of paint that can be applied to new or existing structures. The paint can incorporate any number of conductive materials, such as copper, making it relatively inexpensive.

Electrodes are applied around the perimeter of a structure. The sensing skin is then painted onto the structure, over the electrodes. A computer program then runs a small current between two of the electrodes at a time, cycling through a number of possible electrode combinations.

Every time the current runs between two electrodes, a computer monitors and records the electrical potential at all of the electrodes on the structure. This data is then used to calculate the sensing skin’s spatially distributed electrical conductivity. If the skin’s conductivity decreases, that means the structure has cracked or been otherwise damaged.

The researchers have developed a suite of algorithms that allow them to both register damage and to determine where the damage has taken place.

2. Accoya Acetated Wood (below)

Source: AccoyaExtensive laboratory and field testing by leading institutes around the world (including in New Zealand, USA, UK, Sweden, Malaysia, Indonesia, the Netherlands and Japan) has shown the performance of acetylated wood to be extremely reliable and long lasting.

Accoya® wood has been thoroughly tested for dimensional stability, durability, paint retention and in-ground conditions to ensure optimal performance. Indeed, it is so reliable that for many years it has been – and continues to be – used by scientists as the benchmark against which other treatments and modifications are measured.

How Does It Work?

Cellulose is a major structural ingredient of wood but it is also a major food source for several different insects and decay fungi and makes a great shelter for others, too. Rot causes wood to degrade – particularly when it is used outdoors and exposed to moisture – limiting its service life. Thanks to the acetylation technology pioneered by Accsys Technologies, Accoya wood offers you an environmentally compatible, durable wood that can be used with confidence in outdoor applications and will last for many, many years. As ‘Class 1’ suggests, this is simply the best level of durability possible in wood.

"Accoya is non-toxic and made from sustainably grown timber and these things were also considerations,” said Sieds Hoitinga, Project Manager, Province of Friesland, the Netherlands.

Accoya wood’s durability makes it very long lasting, at least:

50 years above ground

25 years in-ground or freshwater contact

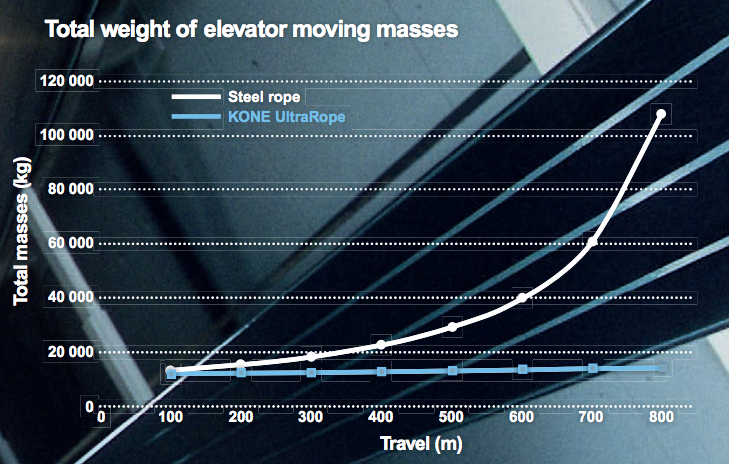

3. Carbon Fibre Elevator Rope (below)

One major problem in developing skyscrapers is elevator technology; at a certain height, the amount of steel rope required to pull passengers up becomes too heavy and the number of separate elevators needed to reach the top, well, skyrockets. Finnish company Kone has developed an alternative: A rope made of carbon fibre that's 90 per cent lighter and could support elevators up to twice as high as the current limit.

Cue the company's UltraRope: this elevator-hoisting material could enable elevators up to a kilometre in height. It will also change how elevators are serviced, since it will last twice as long than standard steel rope.

How Does It Work?

The technology eliminates the disadvantages of existing steel ropes – high energy consumption, rope stretch, large moving masses, and downtime caused by building sway. Kone's UltraRope is ultra-light with a carbon fiber core surrounded by high-friction coating which has excellent strength properties.

The coating is highly resistant to wear and abrasion and is less sensitive to building sway frequencies that can cause elevator downtime during high winds.

4. Wallpaper That Charges Your Phone (below)

"Imaging your world untethered" is the catchcry of UBeam's website, and that's exactly what the company is aiming to do.

With pioneering ultrasound technology, uBeam creates an aura of safe, wireless energy that charges your personal devices, keeping them all in perfect orbit. The company is building the energy infrastructure of the future, helping us all cut the cords once and for all, ultimately charging with ultrasound.

The uBeam wireless charging stations - which will act like WiFi, allowing users to walk around a space while charging - will be thin, measuring no more than 5 millimeters thick. These transmitters could be tacked to walls like wallpaper or made into decorative art to beam electricity to devices. Smartphones and laptops could then be equipped with thin receivers able to convert audio and charge the devices.

With its first prototype released in 2014, the company is well on its way to delivering a product to market.

How Does It Work?

A transmitter transmits inaudible sound, emitting focused power to receivers that are actively requesting power. The receiver then picks up sound and converts it into usable electricity using the company's energy harvesting technology.

Transmitters can be attached to anything - including wallpaper - which can wirelessly charge devices.

5. Roman Concrete (below)

The buildings and structures of ancient Rome have stood for thousands of years, and now research has proved the Romans are the undisputed kings of building with their original formulas lasting centuries in addition to being greener than modern concrete formulas.

Now, researchers from Berkeley Lab at the University of California have made a breakthrough in cracking the secret of their long life - the special formula the Romans used to make their concrete. Unlike modern concrete, in which Portland cement is used to bind the aggregate, Roman concrete uses a mortar mix of volcanic limestone, which reacts to form crystals that expand into the space within the concrete more effectively.

This performs the function of microfibres in Portland-based concrete, but better - more resistant to corrosion, and packing the space more tightly and reducing the risk of microcracking in the concrete over time, extending lifespan considerably - thousands and thousands of years.

How Does It Work?

Roman concrete is not just stronger than today's version, it is also much greener. The limestone and clay used in Portland cement needs to be heated to over 1,400 degrees celsius in the manufacturing process, and this accounts for 7 per cent of global carbon emissions. But Roman concrete doesn't need nearly as much heat, as the volcanic ash and lime they used reacts at a lower temperature. This means a potential new concrete formula that is stronger, greener, and longer lasting.