US Marines Build World First 3D Printed Concrete Barracks

Emerging technologies, such as robotics, 3D printing and autonomous equipment is a burgeoning multi-billion dollar industry.

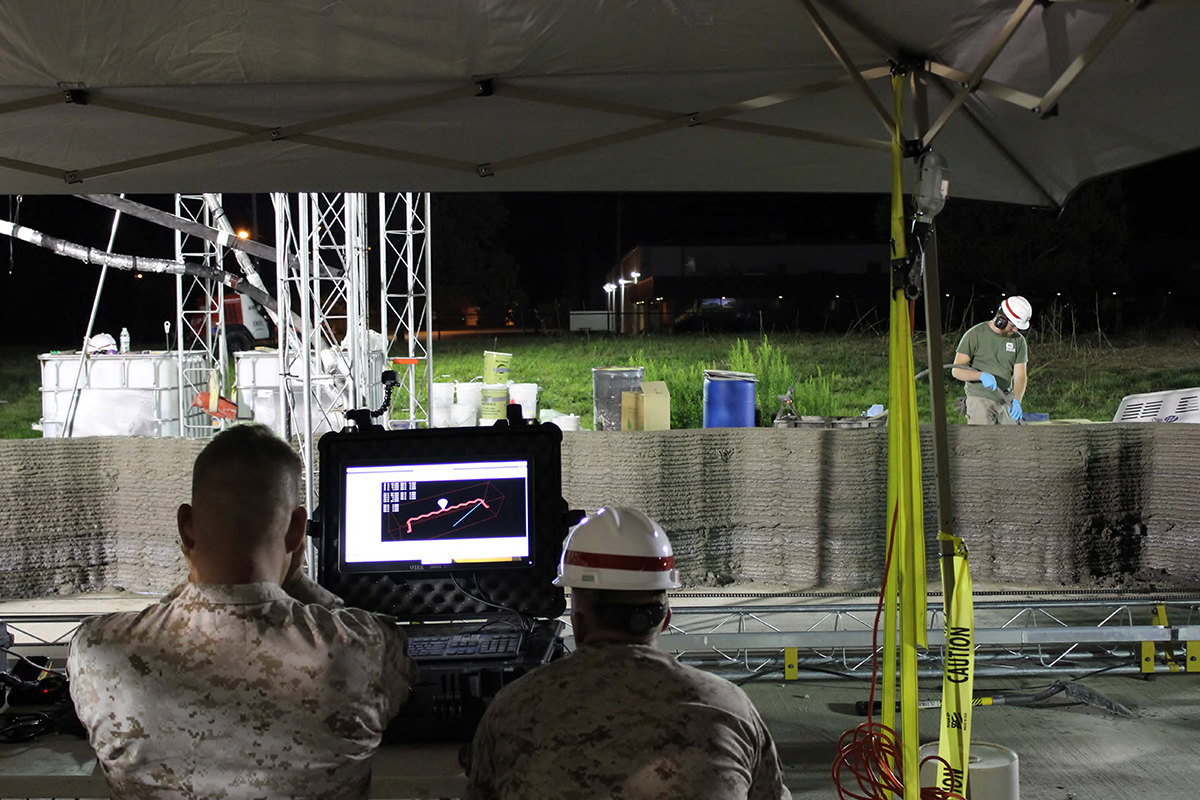

Recognising it also has the potential to save lives, in a world first, the US Marine Corps have teamed up to operate the world's largest concrete 3D printer.

The ability to build structures while putting fewer people in danger is a significant incentive to utilise cutting-edge technology and autonomous systems. One the US Armed Forces have adopted.

Last month, an expeditionary concrete 3D printer was used to print a 500-square-foot barracks hut in just 40 hours. This time frame is drastically shorter than the five days it normally takes 10 Marines to construct a barracks hut out of wood.

“This exercise had never been done before,” Captain Matthew Friedell said.

“People have printed buildings and large structures, but they haven’t done it onsite and all at once. This is the first-in-the-world, onsite continuous concrete print.”

In building the structure, located at the Army Engineer Research and Development base Illinois, the team started with a design model on a 10 year old computer, concrete and a 3D printer.

The job took 40 hours purely because Marines had to monitor the printer and fill it with concrete. Although Friedell said if there was a robot to do the mixing the building could have been finished within a single day.

Related: Australian Bricklaying Robot Could Build 30 Million New Homes Globally

Robots should be doing everything that is dull, dangerous and dirty, and a construction site on the battlefield is all of those things.

--Captain Matthew Friedell

In active or simulated combat environments, it makes sense marines shouldn't be out there swinging hammers and holding plywood, Friedell explained.

“Having a concrete printer that can make buildings on demand is a huge advantage for Marines… The more we can pull Marines out of those potentially dangerous situations, whether it’s active combat or natural disaster, and place robotics there instead, it helps us accomplish the mission more efficiently.”

During humanitarian or disaster relief missions the technology also provides a way forward to quickly deliver shelter, schools and community buildings.

“We can bring forward better structures, houses and forward operating bases with less manpower and fewer Marines in harm's way,” Friedell said.